Manufacturing excellence depends on precision, not just in production, but in how knowledge is managed throughout your organization. When critical documentation is scattered across email threads, shared drives, and paper binders, the consequences extend far beyond frustration. They manifest as real production delays, quality inconsistencies, and safety risks.

This fragmentation of critical information doesn’t just slow operations; it creates tangible business risks. When your team can’t quickly access the knowledge they need, equipment stays down longer, quality suffers, and training new personnel becomes increasingly difficult. Let’s explore how implementing a structured internal knowledge base like AllyMatter can transform these challenges into opportunities for operational excellence.

1. Reduce production downtime with centralized maintenance documentation

Every minute of unexpected downtime in manufacturing can cost thousands. When equipment fails, the clock starts ticking. Technicians who must search through disorganized files or rely on calling senior staff waste precious time that could be spent fixing the issue.

AllyMatter’s internal knowledge base centralizes all maintenance logs, troubleshooting guides, and equipment manuals in one searchable repository. The platform’s intelligent organization with smart tags and powerful metadata search means your maintenance team can locate the exact procedure they need in seconds, not hours.

Real-world impact: According to a study, manufacturers lose an average of 800 hours annually to downtime, with an estimated 40% of that time spent diagnosing problems rather than fixing them. A centralized system for maintenance documentation directly addresses this diagnostic inefficiency.

2. Protect intellectual property while enabling necessary collaboration

Manufacturing companies face a unique challenge: sharing essential process information with teams while safeguarding proprietary production techniques. This becomes especially difficult when expanding into new markets or working with global partners.

AllyMatter solves this through granular access control that lets you determine exactly who sees what. Quality control procedures can be shared widely, while proprietary methods remain visible only to key personnel. The platform’s role-based security policies ensure your intellectual property stays protected without hindering necessary communication.

Each document can be assigned specific visibility settings:

- Fully public (accessible to anyone)

- Internal users only (for authenticated team members)

- Private to user (creator-only access)

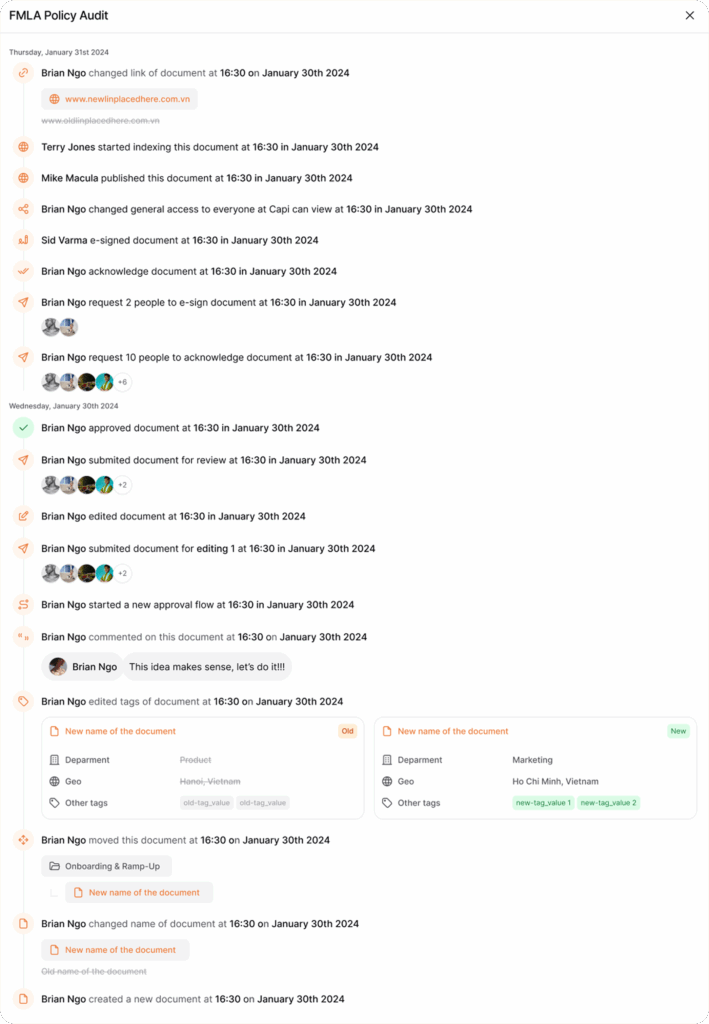

3. Streamline compliance management for manufacturing standards

Manufacturing compliance isn’t optional. From safety regulations to quality certifications, the documentation burden is substantial and the consequences of non-compliance severe.

AllyMatter’s comprehensive audit trail tracks every edit, update, and action on your compliance documents. The detailed change history makes preparing for audits straightforward rather than stressful. When auditors request documentation history, you can provide it in moments rather than spending days compiling evidence.

For critical safety and compliance procedures, AllyMatter offers multiple acknowledgment methods:

- Platform acknowledgment buttons

- Third-party e-signature* integration

- Chat notifications

(*This feature is under development.)

This ensures your team has not only seen important safety protocols but formally acknowledged them – creating accountability and helping meet legal obligations.

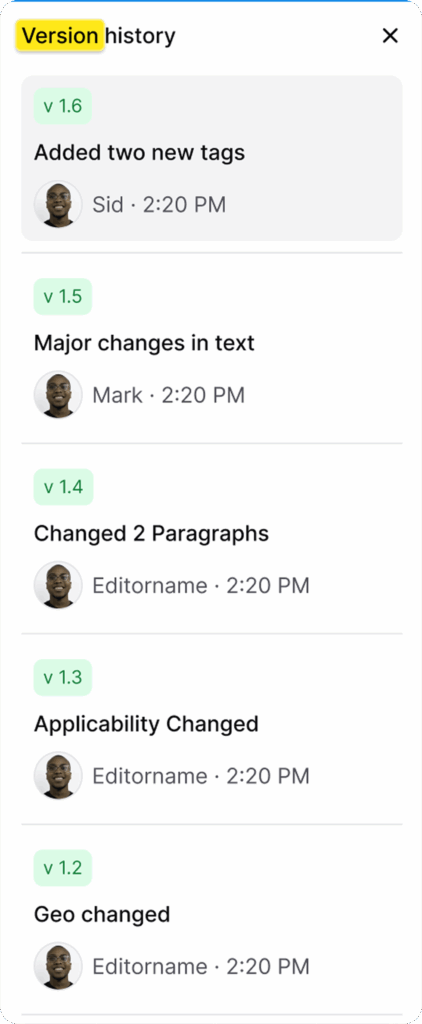

4. Standardize processes across multiple production facilities

Consistency is the backbone of manufacturing quality. When different facilities follow slightly different procedures, product quality inevitably varies. Yet maintaining standardized processes across multiple locations has traditionally been challenging.

AllyMatter creates a single source of truth for standard operating procedures. When processes are updated, the changes are immediately available to all facilities. Version control prevents teams from working with outdated documentation.

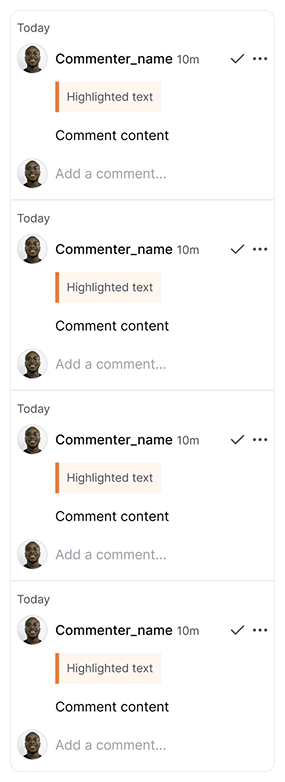

The most successful manufacturing companies treat their SOPs as living documents. You can use AllyMatter’s comment box feature to collect feedback from production teams about how procedures work in practice, then incorporate improvements regularly.

5. Preserve critical production knowledge before it walks out the door

Manufacturing relies heavily on experienced personnel who carry years of specialized knowledge. When these team members retire or leave, their expertise often goes with them.

A 2021 Manufacturing Institute study found that 77% of manufacturers anticipate ongoing difficulties in attracting and retaining workers. This challenge is compounded by research from Panopto, which found that 42% of institutional knowledge is unique to individual employees and isn’t documented elsewhere in the organization. This workforce volatility makes knowledge preservation critical.

AllyMatter helps capture tribal knowledge systematically through:

- Structured documentation templates

- Multimedia content including images and videos

- Collaborative editing that allows experts to review and refine content

By converting individual knowledge into organizational assets, manufacturing companies become more resilient to staff turnover and create valuable resources for training new team members.

6. Accelerate new operator training and certification

The skills gap in manufacturing is well-documented. Training new operators efficiently is essential for maintaining productivity, especially as experienced workers retire.

AllyMatter transforms operator training by organizing materials logically with visual aids. Training managers can create comprehensive onboarding sequences. New operators can find answers to their questions independently rather than constantly interrupting more experienced staff.

For certification tracking, the platform’s document acknowledgment features ensure compliance requirements are met and properly documented. Training progress becomes transparent and measurable rather than ambiguous.

7. Improve cross-functional communication between design and production

The handoff between product design and manufacturing is often a troublesome point. Engineers may create specifications without full awareness of production constraints, while manufacturing teams struggle to interpret design intent.

AllyMatter bridges this gap by creating a unified platform where both teams can collaborate. Engineering specifications and production requirements all live in one place with clear version control. Comments and feedback flow directly between departments, reducing misunderstandings and rework.

By breaking down information silos, the platform helps manufacturing companies implement design for manufacturability principles more effectively, leading to smoother production launches and fewer costly design revisions.

8. Manage supplier specifications and quality requirements efficiently

Manufacturing quality begins with suppliers. Tracking component specifications, material safety data sheets, and quality agreements is essential but administratively burdensome.

AllyMatter centralizes all vendor-related documentation with custom tags for easy retrieval. When supplier specifications change, the system maintains a complete history of previous requirements, making it easy to trace quality issues to their source.

For companies managing dozens or hundreds of suppliers, the platform’s search functionality means you can pull up critical information during supplier meetings without delay, strengthening your negotiating position and improving supplier relationship management.

9. Support lean manufacturing and continuous improvement initiatives

Continuous improvement requires a clear understanding of current processes before making changes. Without well-documented baseline procedures, improvement efforts often fail to deliver measurable results.

AllyMatter supports lean manufacturing principles by:

- Documenting standard processes as the foundation for improvement

- Tracking changes and their impact through version history

- Making best practices immediately available across the organization

When a process improvement proves successful in one area, it can be quickly standardized across all production lines or facilities, multiplying the benefit throughout the organization.

10. Enhance safety management with accessible protocols

Manufacturing safety depends on clear procedures that are easily accessible in critical moments. When safety protocols are buried in filing cabinets or complex digital systems, they’re less likely to be followed consistently.

AllyMatter makes safety documentation immediately accessible through intuitive organization and powerful search capabilities. This ensures that safety information is available wherever work is happening – on the production floor, not just in the office.

For regulated industries, the platform’s audit trail provides verification that safety procedures have been reviewed and acknowledged by appropriate personnel. This creates not only safer working conditions but also documented evidence of safety compliance.

Turn knowledge into your manufacturing advantage

In manufacturing, operational excellence depends on effectively managing knowledge assets. AllyMatter transforms scattered documentation into a strategic resource that reduces downtime, preserves critical expertise, and drives continuous improvement.

Unlike general file storage systems, AllyMatter is built specifically for knowledge management with features tailored to the needs of growing companies. From granular access controls to audit trails and acknowledgment workflows, the platform addresses the unique documentation challenges manufacturing companies face daily.

Ready to see how AllyMatter can help your manufacturing operation eliminate knowledge chaos? Join our waitlist.

Frequently asked questions

How does AllyMatter differ from general file storage systems for manufacturing documentation?

Unlike basic file storage, AllyMatter provides intelligent organization with smart tags, granular access controls, and comprehensive audit trails specifically designed for knowledge management. Manufacturing teams can find critical information through powerful metadata search rather than browsing folder structures, and the platform tracks who accessed what documentation for compliance purposes.

Can AllyMatter integrate with our existing manufacturing execution systems?

While AllyMatter serves as a centralized knowledge repository, it’s designed to complement your existing systems rather than replace them. The platform can store documentation, procedures, and references that support your MES operations, creating a unified knowledge layer that enhances rather than disrupts current workflows.

How quickly can manufacturing teams be trained on AllyMatter?

AllyMatter’s intuitive interface requires minimal training. Most manufacturing teams become proficient within a few days of basic orientation. The platform’s simple search functionality and logical organization mean operators can find information independently without extensive technical training.

What happens to our documentation if team members leave during implementation?

AllyMatter specifically addresses knowledge preservation during transitions. The platform captures tribal knowledge in structured formats, ensuring critical manufacturing expertise remains accessible even when experienced personnel leave. Version control and collaboration features help maintain institutional knowledge continuity.

How does AllyMatter support multi-facility manufacturing operations?

The platform creates a single source of truth across all locations while allowing facility-specific customization through access controls. Updates to standard procedures are immediately available to all facilities, while site-specific documentation can be restricted to relevant personnel, maintaining both consistency and flexibility.