Turn Process Chaos Into Operational Consistency

Give your operations teams standardized procedures, safety protocols, and quality controls they can actually find and follow.

Every Operations Manager Knows These Moments

Equipment goes down during night shift

Your day team documented the fix, but it's buried in an email thread from three months ago. Night shift improvises while production stops.

New location opens with quality issues

They're making mistakes your main facility solved years ago because best practices exist only in the day manager's memory.

Safety audit reveals inconsistent procedures

Some teams follow the updated protocol, others use the old version, and a few made up their own approach because they couldn't find documentation.

Process improvement sits unused

You spent months optimizing the workflow at one site, but six months later the other locations still don't know it exists.

Vendor renewal deadline approaches

Contract details are scattered across emails, drives, and notebooks. You can't find service agreements or contacts when you need them most.

Standardize. Document . Scale.

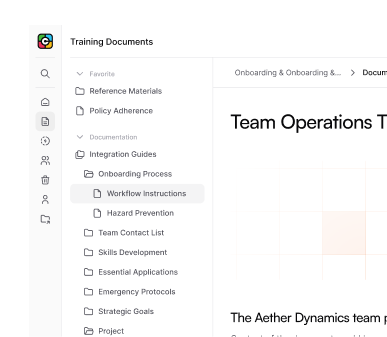

Single Source for All Procedures

Every process, safety protocol, and quality standard stored where every team member can access it instantly.

Lightning-Fast Process Search

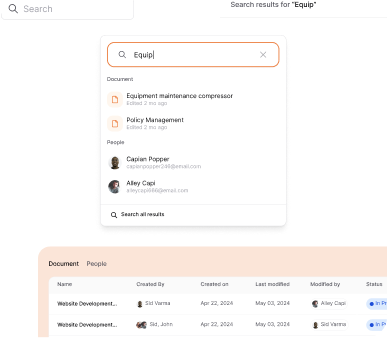

Find the exact procedure, vendor contact, or safety protocol in seconds while operations continue smoothly.

Guaranteed Process Updates

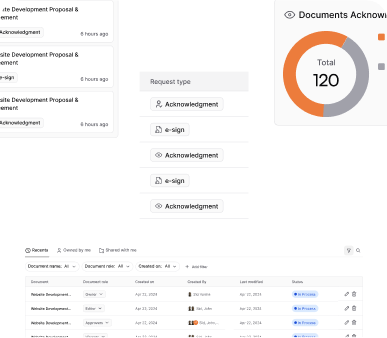

When procedures change, every team must read and acknowledge them before their next shift.

Find Any Process While Operations Keep Running

Stop halting production to hunt for procedures. Our search delivers exact processes instantly type "equipment maintenance compressor" and get the complete protocol, not a folder of outdated documents. Your teams stay productive, downtime drops, and quality stays consistent.

Never Have Teams Follow Outdated Procedures

When you update safety protocols or process improvements, the system requires every team member to read and acknowledge changes before their next shift. No more discovering procedure confusion during audits or incidents. Managers see exactly who's current on which processes.

Standardize Every Operational Process

Access documented procedures for maintenance, quality checks, safety protocols, and vendor management. Maintain operational flexibility while ensuring compliance and consistency. New team members execute complex processes correctly from day one instead of learning through trial and error.

Build Training Programs on Your Documentation

With all your operational knowledge centralized in one searchable location, you can create structured training programs that reference the same procedures teams use daily. When everything lives in one place, training becomes more effective and compliance becomes simpler.

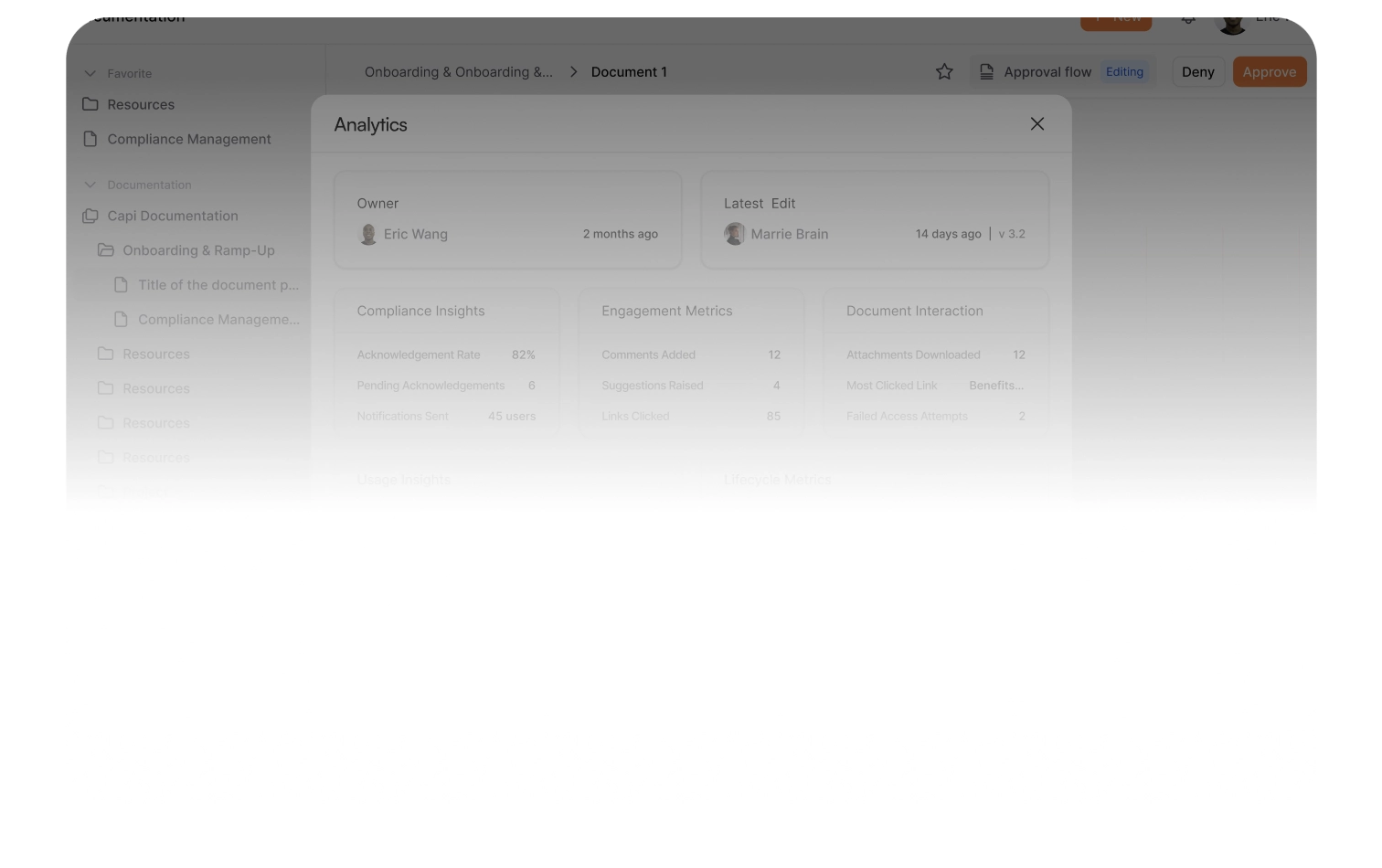

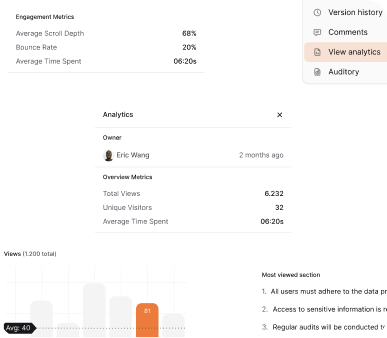

Managers See Which Processes Teams Actually Use

Track which procedures get accessed most, identify knowledge gaps that cause delays, and see who's engaging with new processes. Spot training needs before they become quality issues. Prove compliance for audits with detailed reading analytics and process adoption tracking.

Turn Expert Knowledge Into Standard Operating Procedures

Your senior technicians know how to handle equipment failures and process exceptions. Now that knowledge is documented in clear SOPs anyone can follow. Any shift can resolve complex operational issues confidently instead of waiting for the expert or improvising solutions.

Works Inside Your Daily Operations Tools

Get notified about new procedures that need acknowledgment directly in your team channels - on Slack and Teams. Share helpful process links with colleagues without switching applications.

Standardize Your Operations Fast

Implementation is designed to be quick and straightforward. AllyMatter can migrate your existing operational documentation for you. Your teams can start benefiting from standardized, searchable processes in a matter of days, not weeks or months.

What This Means for Your Operations Team

Consistent Quality

Every location and shift follows the same proven procedures, eliminating variation and reducing defects.

Smooth Knowledge Transfer

New locations and team members get up to speed quickly with documented best practices instead of reinventing processes.

Faster Problem Resolution

Find solutions in seconds instead of minutes, keeping production running and costs controlled.

Reliable Safety Compliance

Every team member has access to current safety protocols, reducing incidents and audit risks.

Built for Operations Teams That Value Consistency

Multi-Location Operations

Stop having different procedures at every site standardize processes across all locations and shifts.

Quality-Focused Manufacturers

Ensure every team delivers the same excellent results with documented procedures and quality controls.

Safety-Critical Industries

Track and prove that teams have read critical safety updates with detailed audit trails and compliance analytics.

Turn Operations Chaos Into Reliable Excellence

Stop making your teams guess at procedures while production waits. See how AllyMatter keeps operations consistent and efficient with instant access to every process they need.

No setup fees. Cancel anytime.

Questions from Operational Teams

i.

Will teams actually use this during production?

Yes. When finding a procedure is faster than asking a supervisor, adoption happens naturally. Most teams see immediate usage because it solves daily operational frustrations.

ii.

What happens when safety procedures change?

Team members can't start their shift until they've read and acknowledged critical safety updates. Managers get compliance reports showing exactly who's current on which procedures.

iii.

How fast is the search during operations?

Fast enough to use while equipment is running. Type partial words or process names and get instant results, no folder navigation or scrolling through documents.

iv.

Can we track training compliance?

Yes. See which procedures teams access most, identify gaps in process documentation, and spot training opportunities before they become quality issues.

v.

Does it work with our current systems?

Integrates with Slack and Microsoft Teams for notifications and collaboration. Teams access procedures directly through AllyMatter's interface for fastest search results during operations.